monoblock 6061-t6 alloy can be oem and ODM high gloss sliver paint

coat all size and pcd

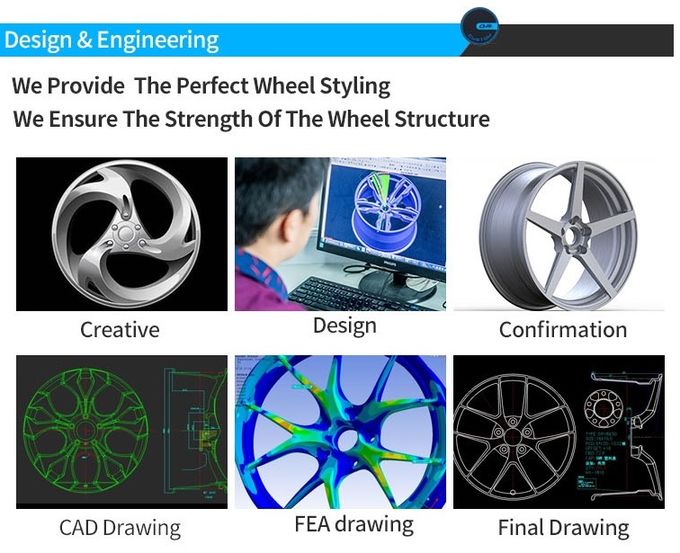

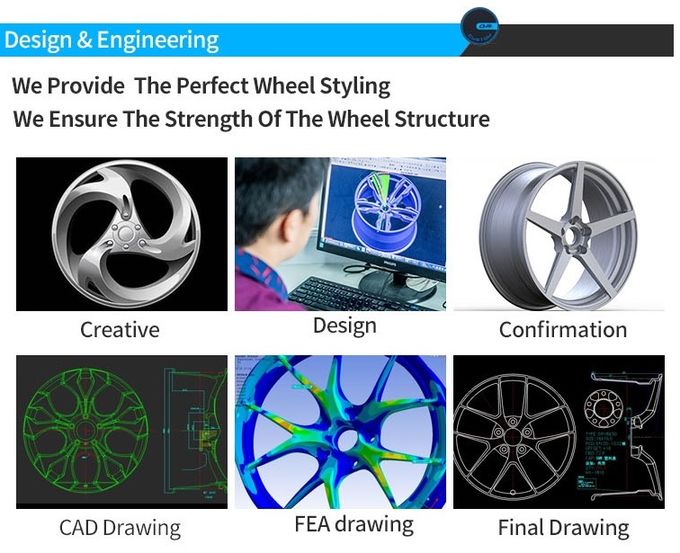

The technological characteristics of forged wheels are roughly as

follows:

In fact, in order to reduce costs, 99% of the wheels on the market

are cast wheels. Only high-end performance models will use high-end

forged wheels. This is not only for more aesthetics and lighter

weight, but also for safety.

| PCD | 5-108 5-112 5-114.3 5-120 5-130 5-139.7 5-135 |

| ET | 10 15 20 23 25 30 38 35 40 45 48 50 |

| Application | VW BMW BENZ PORSCHE LAMBORGHINI TOYOTA |

| Style | 1 Piece 2 Piece 3 Piece |

| Size | 16 inch 17 inch 18 inch 19 inch 20 inch 21 inch 22 inch 23 inch 24

inch |

| WIDTH | 8.5J 9J 9.5J 10J 10.5J 11J 12J |

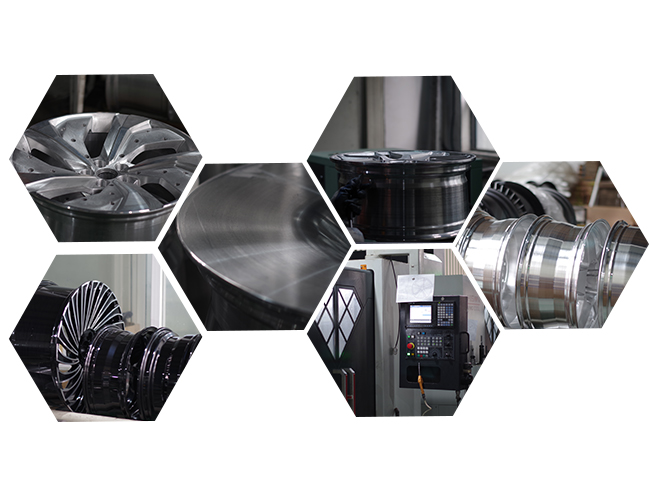

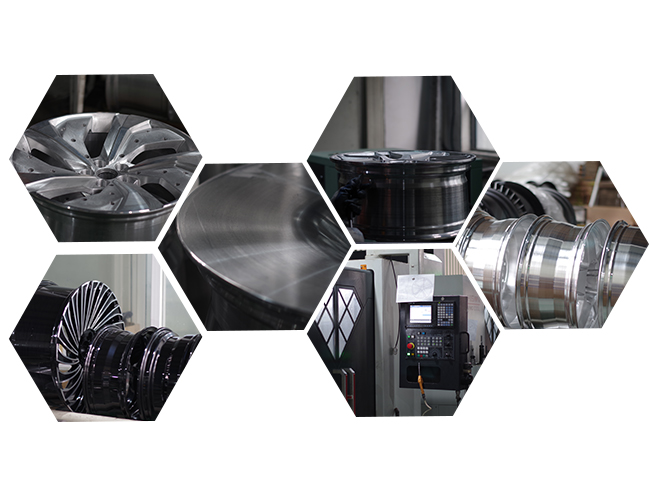

1. The cylindrical design is adopted. The larger the diameter of

the rim is, the thicker aluminum material is used for forging,

which is completely different from the manufacturing method of

using "raw materials" for cast aluminum rims;

2. Cut the aluminum material according to the J number required for

the width of the aluminum ring;

3. First heat the aluminum ingot to around 400 degrees Celsius,

then it is ready for forging;

4. Hot forging and pressing, the higher the tonnage of the forging

press requires the lower the working temperature of the aluminum

ingot, the smaller the grain of the forged product, and the higher

the toughness;

5. The temperature of the rough embryo formed by high temperature

and high pressure is very high, and the surface is covered with

black carbides, which must be handled by a fork motive. The rough

embryo after pickling surface treatment already has the embryonic

shape of a wheel hub;

6. After long-term reprocessing and heat treatment of the T4 and T6

heat treatment machines, the grains of the rough embryo will be

firmer and the toughness of the product will also be improved;

7. Forged aluminum ring must rely on mechanical processing to

process the rough embryo to the rim forming, so the work content

includes bead forming, screw hole drilling, disk turning, detail

processing and other steps;

8. Before painting, you must check the rim surface for flaws.

6061round bar forged and heat treatment

lathe,milling include processing PCD and gas hole

polish,paint ,packaging and install

the order detail: