Brushed Black One Piece Forged Wheels Multi Spoke 20x10

| Material | 6061 t6 aluminum alloy |

| Size | 16 inch 17 inch 18 inch 19 inch 20 inch 21 inch 22 inch 23 inch 24

inch |

| WIDTH | 8.5J 9J 9.5J 10J 10.5J 11J 12J |

| Colour | green black red brown white blue purple gray grey |

| PCD | 5-108 5-112 5-114.3 5-120 5-130 5-139.7 5-135 |

| ET | 10 15 20 23 25 30 38 35 40 45 48 50 |

The technological characteristics of forged wheels are roughly as

follows:

1. The cylindrical design is adopted. The larger the diameter of

the rim is, the thicker aluminum material is used for forging,

which is completely different from the manufacturing method of

using "raw materials" for cast aluminum rims;

2. Cut the aluminum material according to the J number required for

the width of the aluminum ring;

3. First heat the aluminum ingot to around 400 degrees Celsius,

then it is ready for forging;

4. Hot forging and pressing, the higher the tonnage of the forging

press requires the lower the working temperature of the aluminum

ingot, the smaller the grain of the forged product, and the higher

the toughness;

5. The temperature of the rough embryo formed by high temperature

and high pressure is very high, and the surface is covered with

black carbides, which must be handled by a fork motive. The rough

embryo after pickling surface treatment already has the embryonic

shape of a wheel hub;

6. After long-term reprocessing and heat treatment of the T4 and T6

heat treatment machines, the grains of the rough embryo will be

firmer and the toughness of the product will also be improved;

7. Forged aluminum ring must rely on mechanical processing to

process the rough embryo to the rim forming, so the work content

includes bead forming, screw hole drilling, disk turning, detail

processing and other steps;

8. Before painting, you must check the rim surface for flaws.

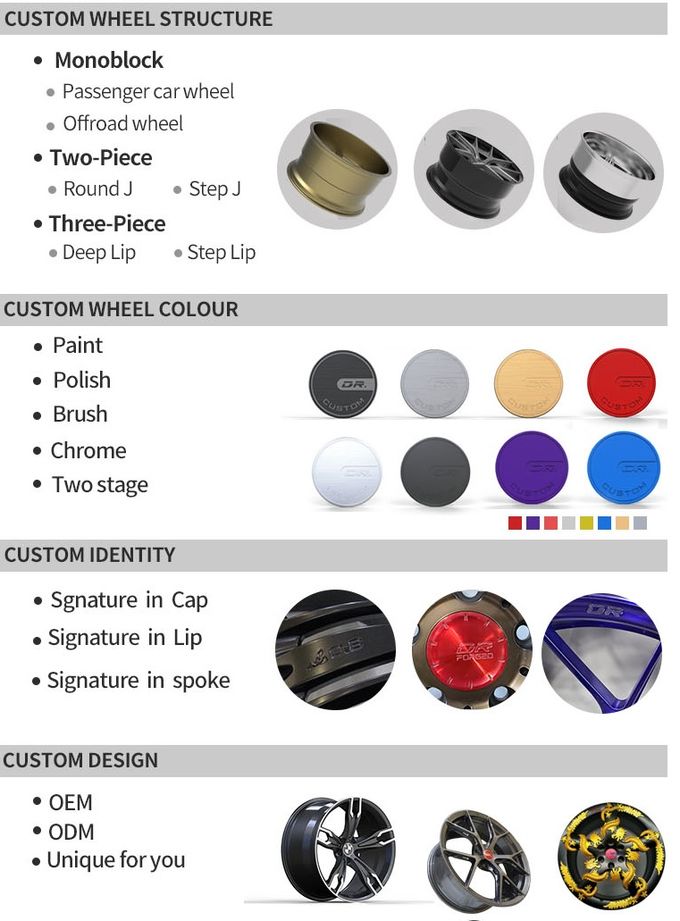

We Can Provide All Kinds Of Structure Type Of Wheels If You Love

Concave,Deep lip &New Ideas...

Tell Us ,It Is Sure To Meet Your Need

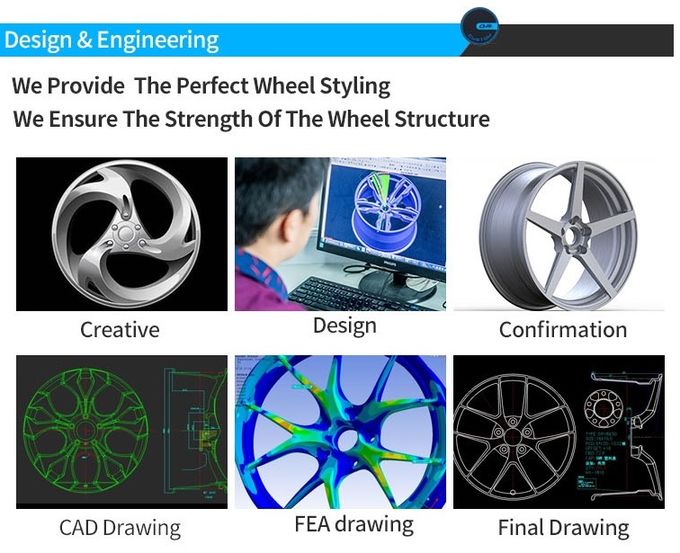

BEST DESIGN AND ENGINEERING

AND EXCELLENT MANUFACTURE

We have 20 horizontal lathes and processing centers produced in US

and Taiwan, 1 set of painting and electrophoresis equipment, and 2

wheel testing machines, which meet all the professional and

personalized needs of customers.

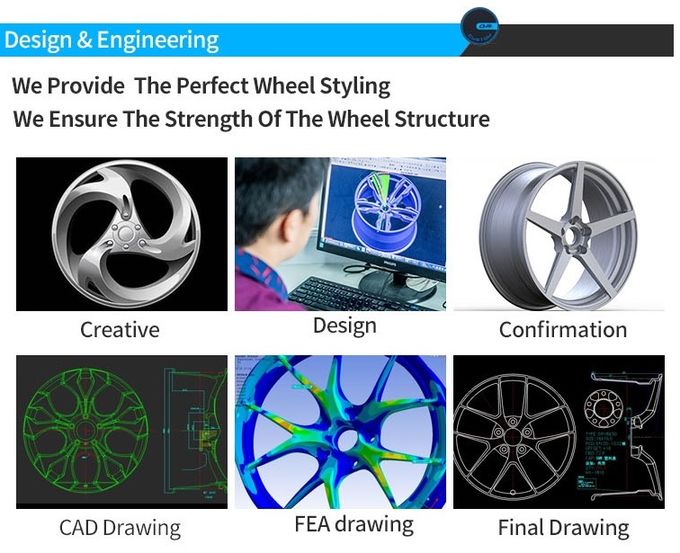

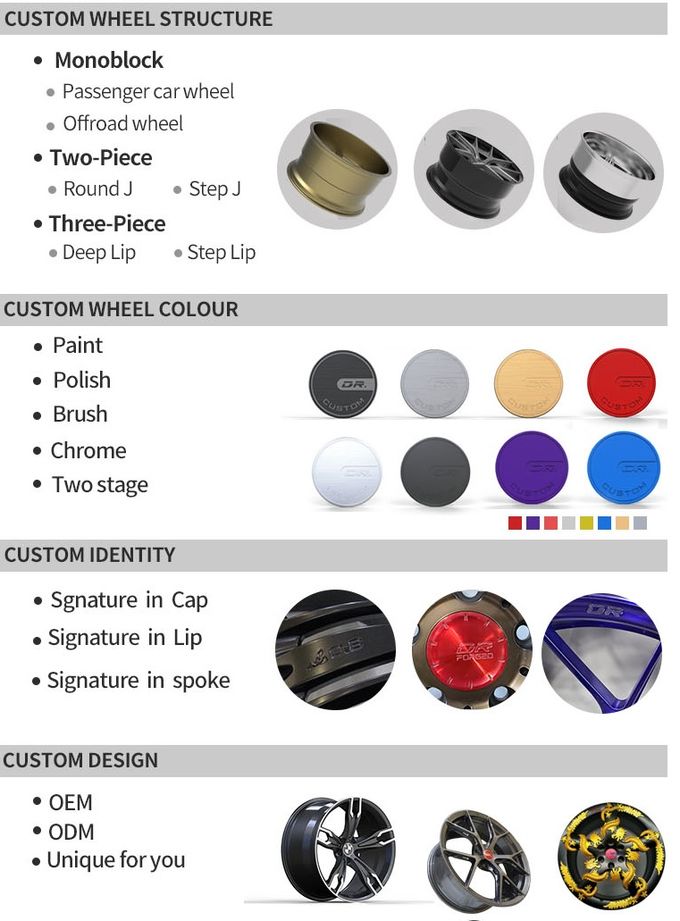

We are specialized in providing one-piece, two-piece and

three-piece forged wheel, and accept customers' modeling, color and

accessories for all-round personalized customization.

The company is located in Songjiang industrial park in the western

suburbs of Shanghai with convenient transportation. It is only 1 km

away from the exit of G60 and G1501 expressways, which makes

communication and guidance with customers very convenient.

FAQ

Q1: How to gurantee the wheel quality?

A: All of our products conform to JWL/VIA standard, undergo

rigorous impact test, cornering fatigue test, radial fatigue test ;

Our factory is ISO/TS16949, ISO14001 TUV SFI JWL/VIA certified.

Q2: How about your delivery time?

A: From the deposit received date, we will finish production within

35-45 days. If need to produce wheel mould, leadtime will takes 3-4

weeks longer.

Q3: What information should I provide for a quotation?

A: Usually we need know : car model and the wheel size , PCD , CB ,

ET(offset) ,color and order quantity to make a correct quoation for

you.

Q4: Do you accept OEM or ODM order?

A: We accept OEM, ODM with customer's logo, wheel design and

packing design.

Q5: What's your MOQ?

A: For our existing mould, MOQ is 80pcs/size/fitment, can mixed

with 2 colors. if need to make your own design, we can discuss

about the MOQ.

Q6: How to deliver your wheels?

A: We cooperate with very reliable shipping company and agent, if

you dont have your own agent, we can help you and give you

suggestions and the most economic way for shipping by sea or by

air, you can choose pickup wheels from the nearest port or at your

shop. |